Originally Posted by Chrystal

View Post

Announcement

Collapse

No announcement yet.

Hunt & O'Byrne Catalog

Collapse

X

-

hopefully you wont be disappointed with it... i have had mine for over 15 years now and i've found it to be a very well made cue and have had no problems with thus far.."Statistics won't tell you much about me. I play for love, not records."

ALEX HIGGINS

-

Yes, I am under the impression that Hunt is very popular in China and Hong Kong. May be more so than in the UK?Originally Posted by Chrystal View PostHi, guys

I just ordered Hunt & O'bourne black plate about 2 months ago, still making.

I got advices from China based snooker forum, H & O is ranked as the number 1 choice compared to other cuemakers. but in this forum, people like TW and MW better than any other cuemakers.

Like what says on MW website, "you get what you pay for", it is the most expensive one i bought, hopefully the best one.

But I think they like Will Hunt and Hunt & O'Byrne more than Hunt & Osbourn.

Members here are very knowledgable. They like TW and MW because these two really are setting the standards out there right now in terms of choice of wood, execution of splices, shaft quality, and so on.

The members here in my opinion also have appreciation for other cues such as Dave Coutt, Robin Cook, Tony Glover, John Parris..and so on. A very few like Acuerate, and no one likes Keith Auld. Last edited by poolqjunkie; 5 August 2009, 12:28 PM.

Last edited by poolqjunkie; 5 August 2009, 12:28 PM.

Comment

-

Hunt & Osborne cues are not bad, but their shafts are to stiff for me, also I don't like the "thick" joint's metal feel, peoples in China like very stiff shaft due to climate and weather is Asia, so their 1st choice was H&O Black Plate,sum up a very very stiff cue with around 4-6 chevrons is the cue they willing to paid 550+ GBP for.Originally Posted by Chrystal View PostHi, guys

I just ordered Hunt & O'bourne black plate about 2 months ago, still making.

I got advices from China based snooker forum, H & O is ranked as the number 1 choice compared to other cuemakers. but in this forum, people like TW and MW better than any other cuemakers.

Like what says on MW website, "you get what you pay for", it is the most expensive one i bought, hopefully the best one.

Comment

-

OK, here is the story in short:

For me H&O is a top cue maker with a great reputation and a nice history.

That was what I am looking for and so I ordered for a friend and me 2 black plate cues in November '08.

Both ash cues with rosewood butt, one cue just with an ebony veneer and a rosewood top splice. And they shuld look somehow like siblings.

We received the cues in Feb. One cue was really fantastic. Nice butt, nice grain in matching color, chevrons aligned with splicing. Everything as it should be. Especially at a top range cue of a top range cue maker.

But the other one was not good. Frayed splicing tips, grain not aligned with splicing, chevrons absolutely not evenly spaced, badge twisted.

I sent Robert an email telling him that I am not happy with the cue.

Robert replied that H&O alignes the splicing to the first chevron from the tip, not to the one closest to the butt . That dark rosewood is very difficult to splice

. That dark rosewood is very difficult to splice  . And that there is no bad craftsmanship....

. And that there is no bad craftsmanship....

Sorry folks, but I really felt bad with that reply, to put it in nice words.

So I told Robert that I expect from a H&O black plate to have a perfectly aligned shaft and good splicing. I have asked in advance if there is ANY concern from their side with the specs and Robert told me there would be no problem.

After some email forth and back Robert agreed to make a new cue with a ebony butt if I'd send the actual cue back at my cost and would bear the shipping cost for the new one. I agreed without being happy after all the discussion and have sent back the cue mid Feb.

I was in London end of May, had a couple of hours time and decided to pop in the H&O workshop to see the guys personally and ask if the new black plate might be finished.

I was really happy to see that the cue was finished and lookes really nice. Then I have seen that the certificate of origin was signed one month before. I have no idea why they did not ship the cue. And then I realized that the cue was 58" while the order was 57".

Robert checked the papers where the 57" were written. Will and Robert told me that this would be no problem, they can easily change that and send me the cue in the next days.

After two weeks I asked when the cue will arrive. After three weeks the cue was there.

The cue was shortened to 57" and retapered to get the 9,5mm

But the 20cm under the ferrule have not been refinished. So a nice finish on the shaft but not in the area under the ferrule. A nice finish on the ebony butt but some mat areas. Also here the badge is twisted.

OK, the story is not short anymore.

Can you understand that I am abit disappointed?

TOP product from TOP cue maker at TOP price?I am confused... Oh wait... Maybe I'm not...

Comment

-

Hi Chrystal,Originally Posted by Chrystal View PostHi Chatlag,

I understand you, it is not only the money but also the long time you have been waiting for. especially when you are expecting to get the best cue from them.

hopefully, i can get my dream cue from H & O.

for me the time was not the big thing. For me the disappointment was that I had the impression that not enough love and pride went into the product. And by far not enough attention to detail.I am confused... Oh wait... Maybe I'm not...

Comment

-

But People in China never knows NICE ARROWS = NO CUE POWER !

People always request for 5~6 even arrows in Front,and 3~4 in Back.

If Someone who are study WOODS like me,they will know,this wood are came from the center of the trees,and the wood are so weak becoz it's young!

It just same with your skin,your muscles.

People will only think center is the best part of the trees.but I am sorry to tell u,it's wrong.Tree is all glow from the center.Not glow from the skin!The part near skin is the most vintage and the oldest part just like our skin.Our skin is born when we are baby until now!

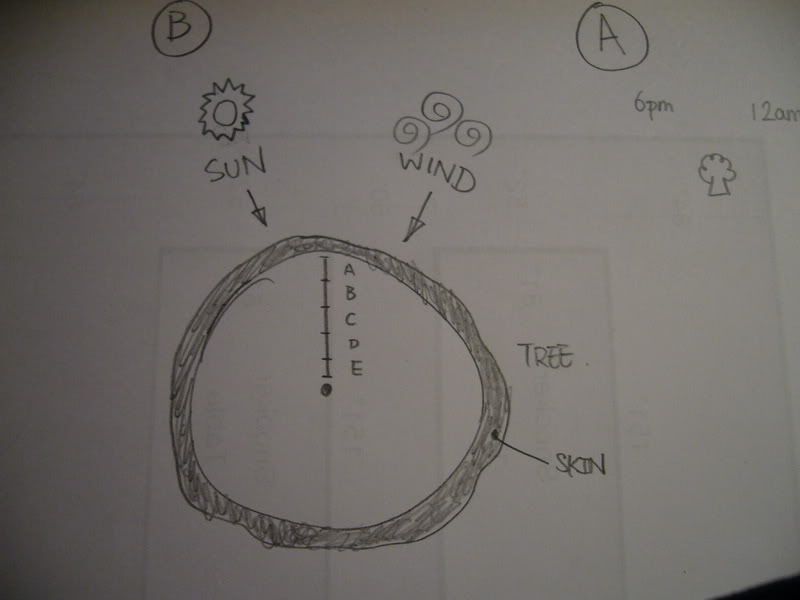

I draw a pic to tell your guy,Please focus on Picture B:

Part A: Hard (high density) with ugly arrows,too much arrows.

Part B: Elasticity,being soild with little ugly arrows

Part C: Middle elasticity,soild with normal arrows

Part D: Being nice arrows

Part E: Low density with nice arrows.Not soild,coz it have too much water

*High Density coz the tree respiration will bring out the waters and make it dry then shrink.

*Low Density can bring the water to whole trees easily.

*Arrows are pneumatocyst,Part A arrow will more coz trees can breath easily;Part E will less arrows,but low density.

*Elasticity just like your woman's skin.Part B & C is in the middle.Density and arrows both are balance.

The result : Part B & Part C is the best Ash for a cues! But no the best arrows.

The cuemakers would use their TAPE to REPAIR Part D & E to be more power!

U can see the old JohnParris,old H&O...Their tape always make more rough.

So...new cues with nice arrows always no much power.Just like O'min,Black Plate.You guys please think about it.Is that right?But I afraid I said too much."要有非凡既生活就要有非凡既付出"

it means

"If u want to have a extraordinary life,u must have a extraordinary devote"

Comment

-

Brother 4,

Very interesting diagram.

I think the arrows you see are the growth rings of the tree. Tree grows at a different rate in winter and summer in most places--in summer they grow faster and in winter they grow slower.

With ash you have two types of grains, namely the dark "lines" and the lighter wood. The dark "lines" are more porous than the lighter region.

Most people like to buy ash/maple from a colder region because wood spends more time in a colder climate which leads them to grow slower, thus offering a higher density.

I believe you were referring to the difference between sap wood and heart wood in your diagram. I think you are right in pointing out that heart wood would be "wetter" than sap wood.

But is it necessarily a good thing to be drier?

Your shaft wood cannot be too dry so to speak once it is made into a cue--if it is really dry, it will absorb moisture from its surrounding until an equilibrium is reached.

A drier piece of wood is also more brittle while a "wetter" piece would display more elasticity.

Technically speaking, a piece of wood with a higher moisture content should be denser than a piece which is drier. It is because the amount of moisture in the wood would add mass per square feet to the wood.

I am not sure if the grains and arrows patterns have to do with whether the wood is sap wood or heart wood. I think it is just hard to find woods with evenly spaced arrows no matter where you look and that is why they are considered premium.

I do agree that the grain pattern should not have a direct bearing on the playability of the cue.

What matters most to the "stiffness" of the shaft should be the weight or density of the shaft wood. It is because the weight would affect directly how much the shaft could vibrate upon impact, or perhaps you can call it the inertia of the wood?

I agree that the taper is important. But with snooker shafts these days most tapers are not really too different. If you look at the volume of wood used on say a 9.5mm shaft on most snooker shafts, the difference is not all that great (may be for a Accurate cue it is much less). So, the weight of the shaft would be determined largely by the density of the wood. The heavier the wood, the less its tendency to vibrate--hence its higher stiffness.

In that sense, the "stiffer" wood should not be the kind coming from sap wood, because sap wood is drier with a lower density.

This is what I believe, and I would like to hear what you and others think about it.

Thank you.Last edited by poolqjunkie; 5 August 2009, 10:42 PM.

Comment

-

Without question mate.Originally Posted by ChatLag View PostOK, here is the story in short:

Can you understand that I am abit disappointed?

Sorry to hear it.

Even top people screw up every now and then. No surprise there. We're all human.

In a case like yours, how willingly suppliers acknowledge responsibilty, how quickly take corrective measures, determines whether they keep a client or not. But even more interestingly because of the internet and forums like this, the "word of web" is much greater and more powerful than the old "word of mouth" and literally hundreds of orders can be lost (or earned) as a result.

That you posted your experience is a favour to everyone!

=o)

Noel

Comment

-

Pics in the cue thread.

Pics in the cue thread.

Comment