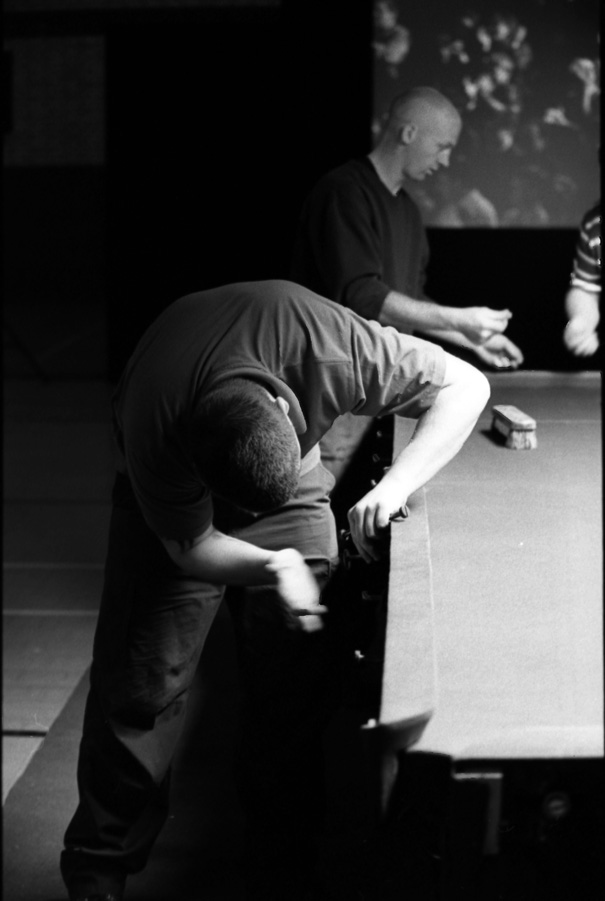

When I was in Oldham in November I had the opportunity to witness how the snooker table was "built" for the exhibition and to take some pictures ...

Actually my interest had been triggered by Semih_Sayginer who had once explained the whole process in the chat ... The captions that explain the pictures on this thread are provided by Semih ... Thanks to him!

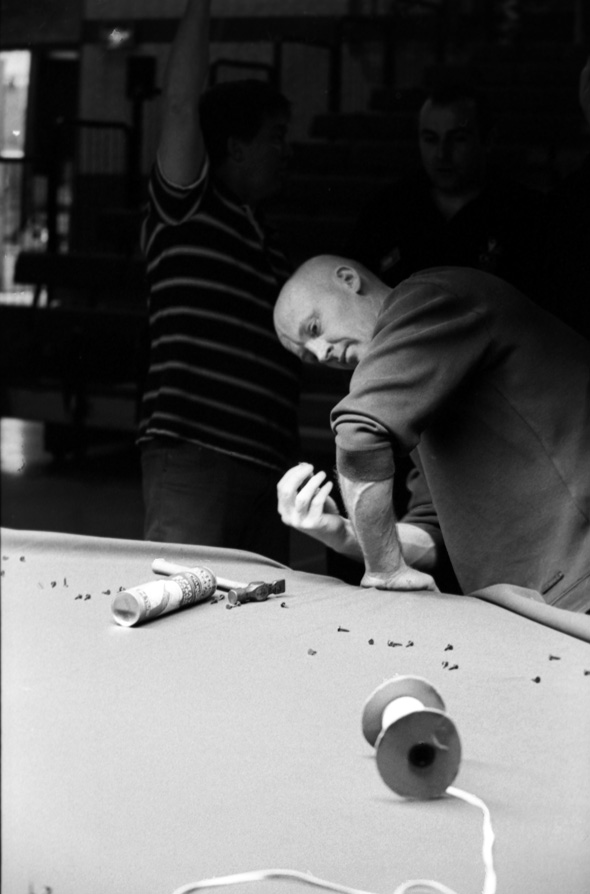

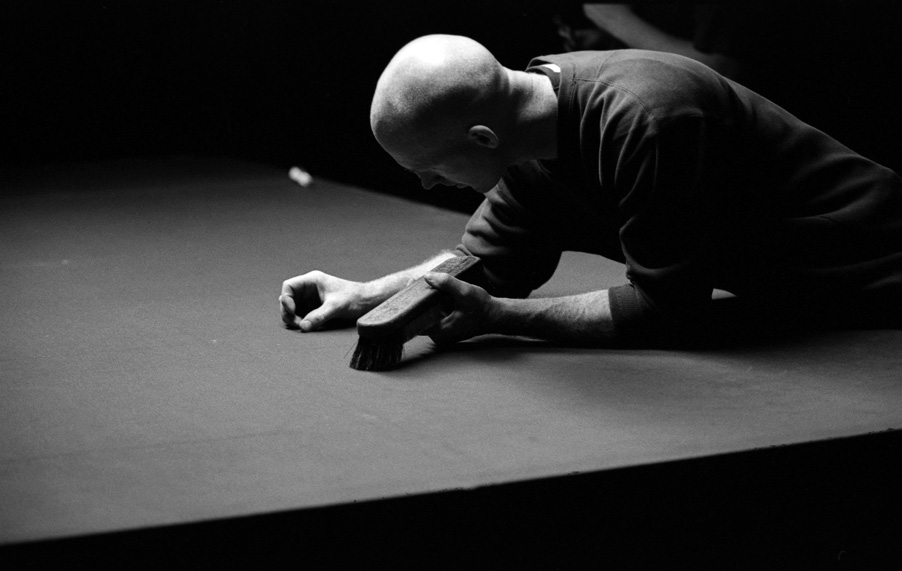

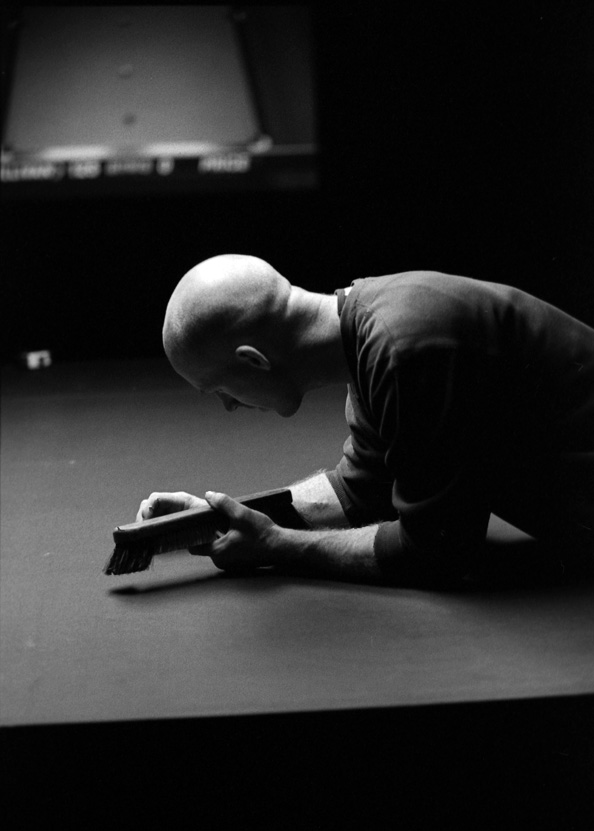

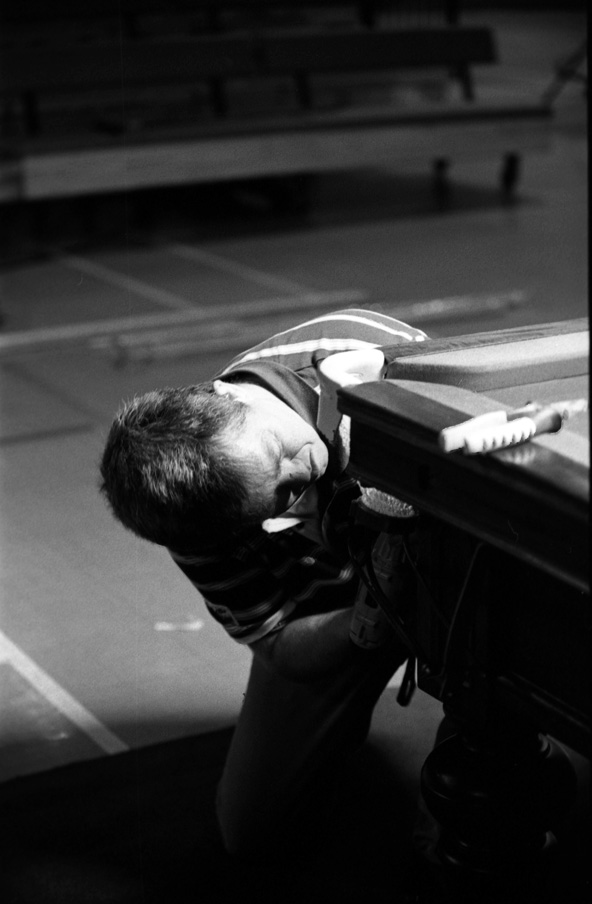

Also I want to thank the fitters ... the guys who actually build the tables and are almost never seen. Their dedication and passion for their job is extraordinary and I had a wonderful day with them!

Let's start ...

The structure of the table used in Oldham was all wood: 8 solid legs supporting a frame and a series of thick cross-pieces forming a bit like a "waffle" pattern. Dimensions of the table are 6x12 feet. The structure of the table is carefully balanced and leveled before the next step is performed.

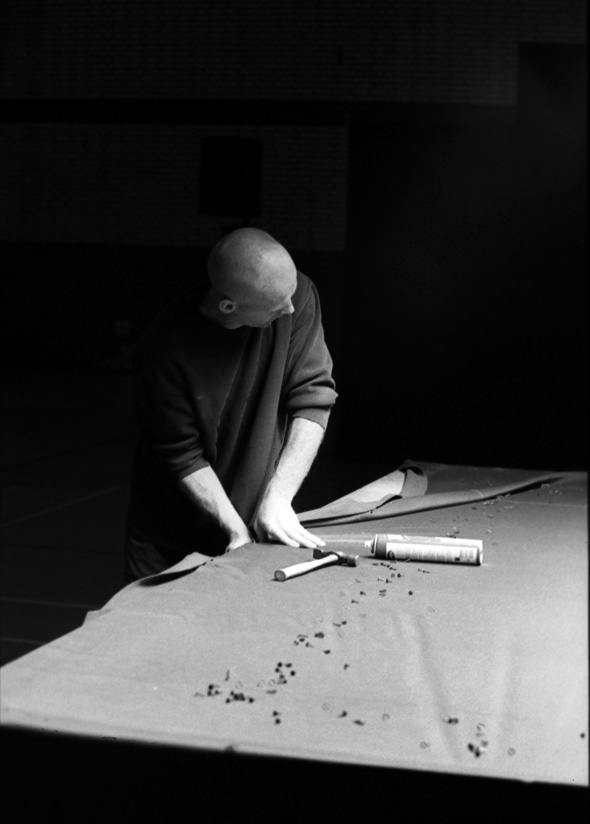

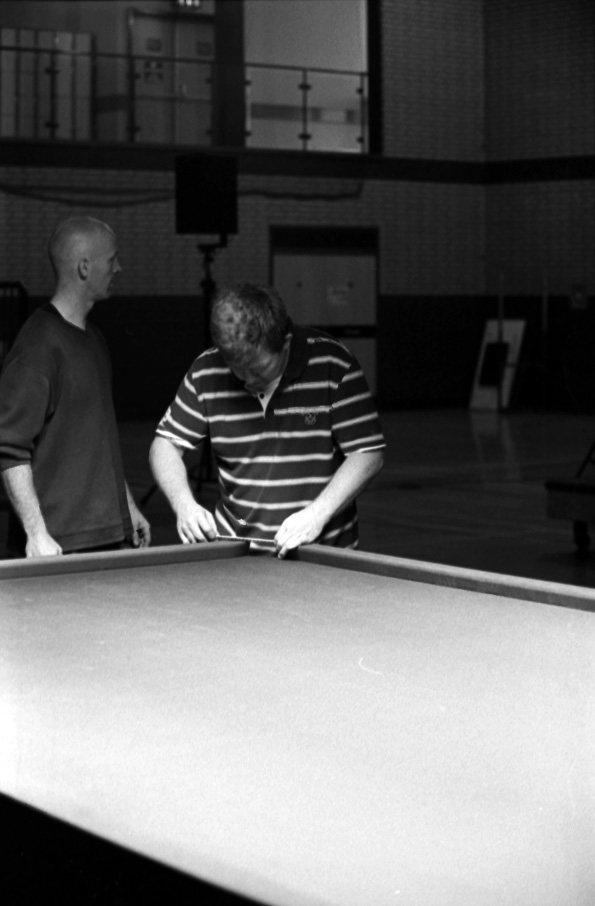

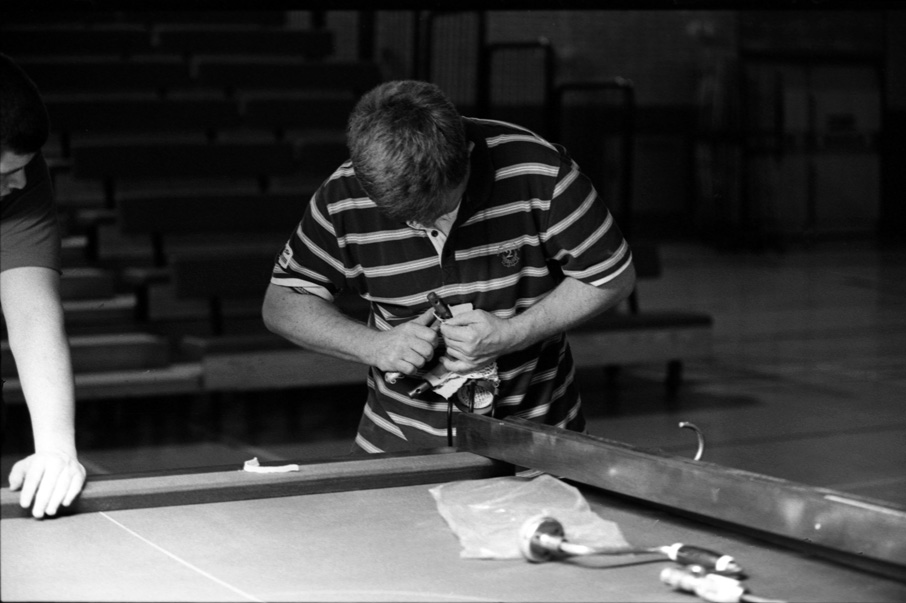

On top of the frame, the bed of table itself is formed by five slate pieces, each weighing over 200 kg. Slate is used because it's heavy, has interesting physical properties to damp vibrations and can be polished very smoothly.

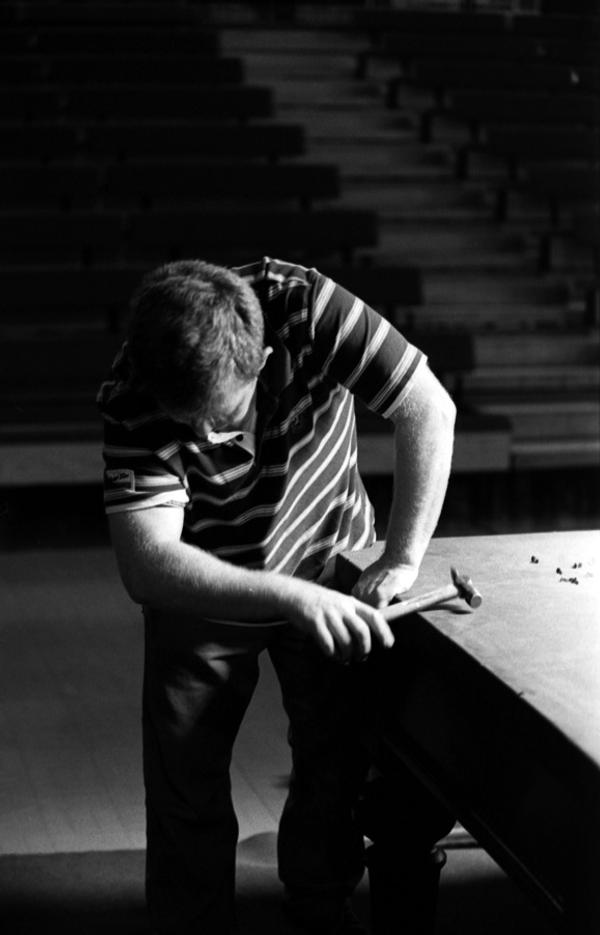

The slates are patched with a patching compound and the whole table surface is rubbed with sand paper to make it perfectly smooth.

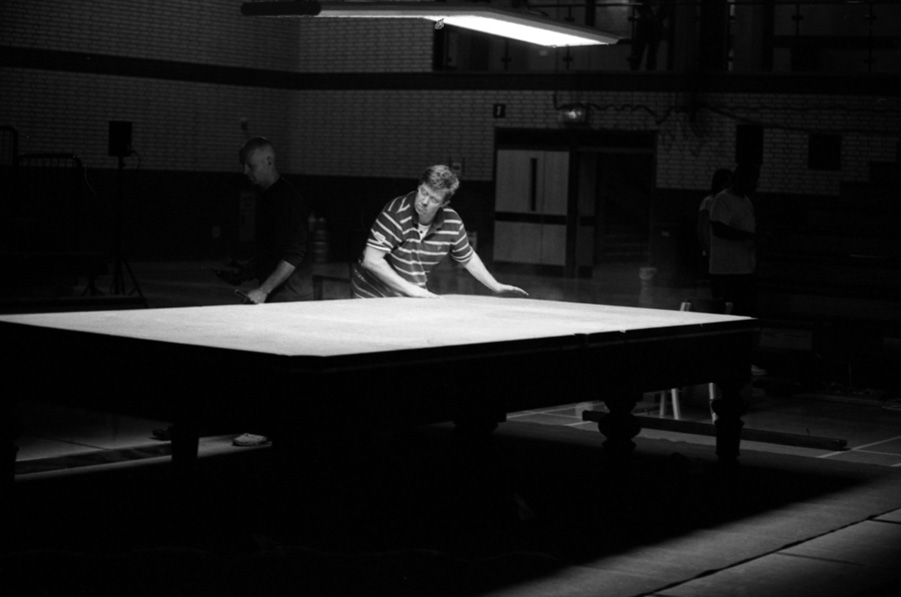

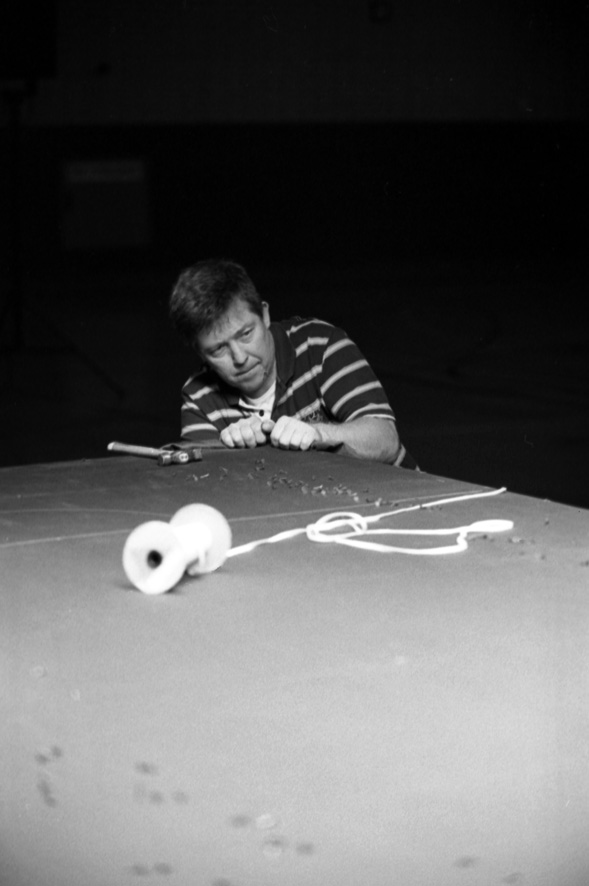

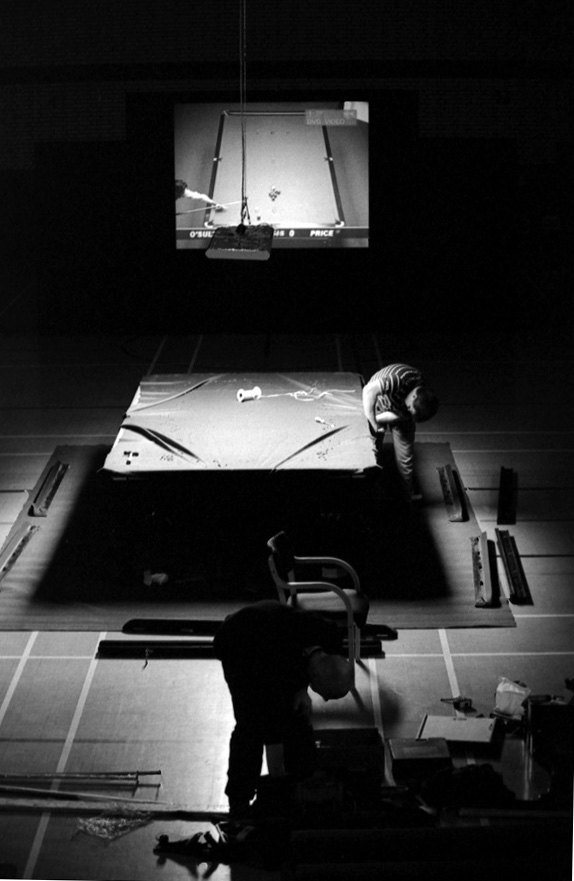

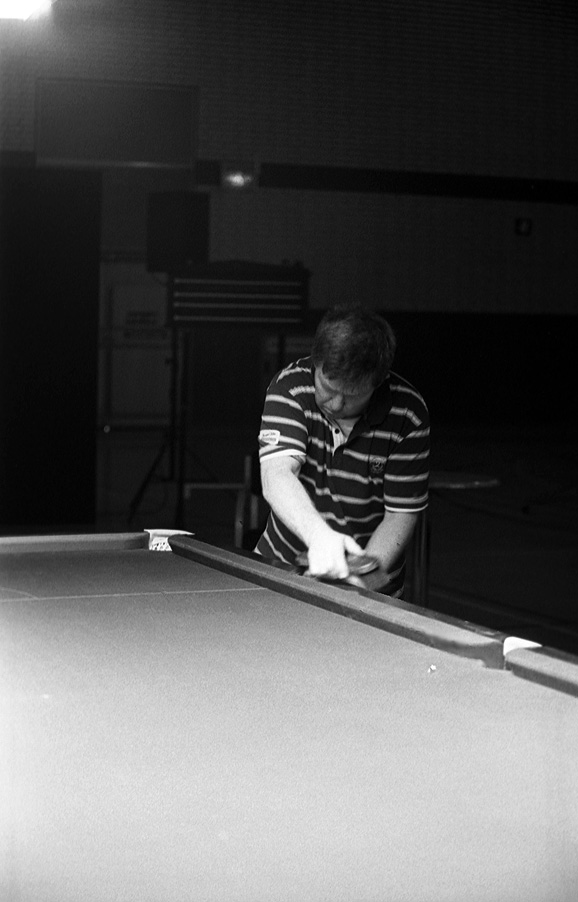

When I arrived at the venue with my camera the slates were already in place ...

So now here is what I saw ...

* The table fitters set up the table lights to their required height above the table. (note this is done after the table is in position as its easier to alter the lights than move the table)

Actually my interest had been triggered by Semih_Sayginer who had once explained the whole process in the chat ... The captions that explain the pictures on this thread are provided by Semih ... Thanks to him!

Also I want to thank the fitters ... the guys who actually build the tables and are almost never seen. Their dedication and passion for their job is extraordinary and I had a wonderful day with them!

Let's start ...

The structure of the table used in Oldham was all wood: 8 solid legs supporting a frame and a series of thick cross-pieces forming a bit like a "waffle" pattern. Dimensions of the table are 6x12 feet. The structure of the table is carefully balanced and leveled before the next step is performed.

On top of the frame, the bed of table itself is formed by five slate pieces, each weighing over 200 kg. Slate is used because it's heavy, has interesting physical properties to damp vibrations and can be polished very smoothly.

The slates are patched with a patching compound and the whole table surface is rubbed with sand paper to make it perfectly smooth.

When I arrived at the venue with my camera the slates were already in place ...

So now here is what I saw ...

* The table fitters set up the table lights to their required height above the table. (note this is done after the table is in position as its easier to alter the lights than move the table)

Comment